Having difficulties to know which product need to restock? Facing customer complains for late delivery due to out of stock?

Product Estimated Restock Time Management is here helps to you to get rid of all the worries. It estimates the stock that can last based on your current stocks and the sales performances. Hence, you are able to restock your stock in time before it is too late.

This feature is only applicable for Unicart Business Gold Plus plan and above.

Step 1: Update Estimated Restock Time and Minimum Quantity

Step 2: View the Report Result

Additional Information

1. Display Products Need to Restock Only

2. Export Products Need to Restock into CSV

3. Forecast Date

Step 1: Update Estimated Restock Time and Minimum Quantity

1. Navigate to Analytics from Unicart Backend Admin, then choose the Restock Time from the Products Report.

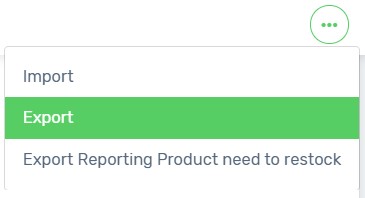

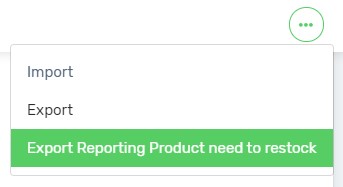

2. Click on More, and select Export.

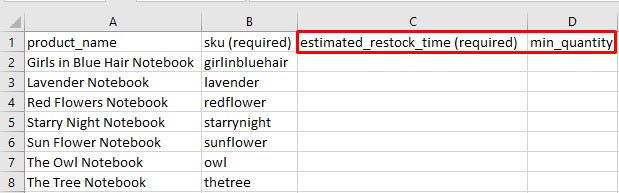

3. Open up the exported CSV file and fill up the column for Estimated Restock Time (days) and Minimum Quantity.

Estimated Restock Time*: The estimated time (days) required for the product to be restock or delivered to you when your purchase from vendors.

Minimum Quantity*: The minimum quantity in stock needed to keep, before the product required to restock.

Note: Insert both of the columns in numbers only.

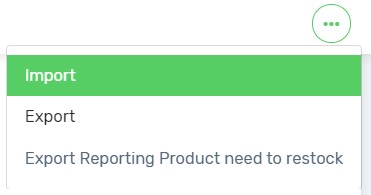

4. After done filled up the information, go to More again and Import the CSV file.

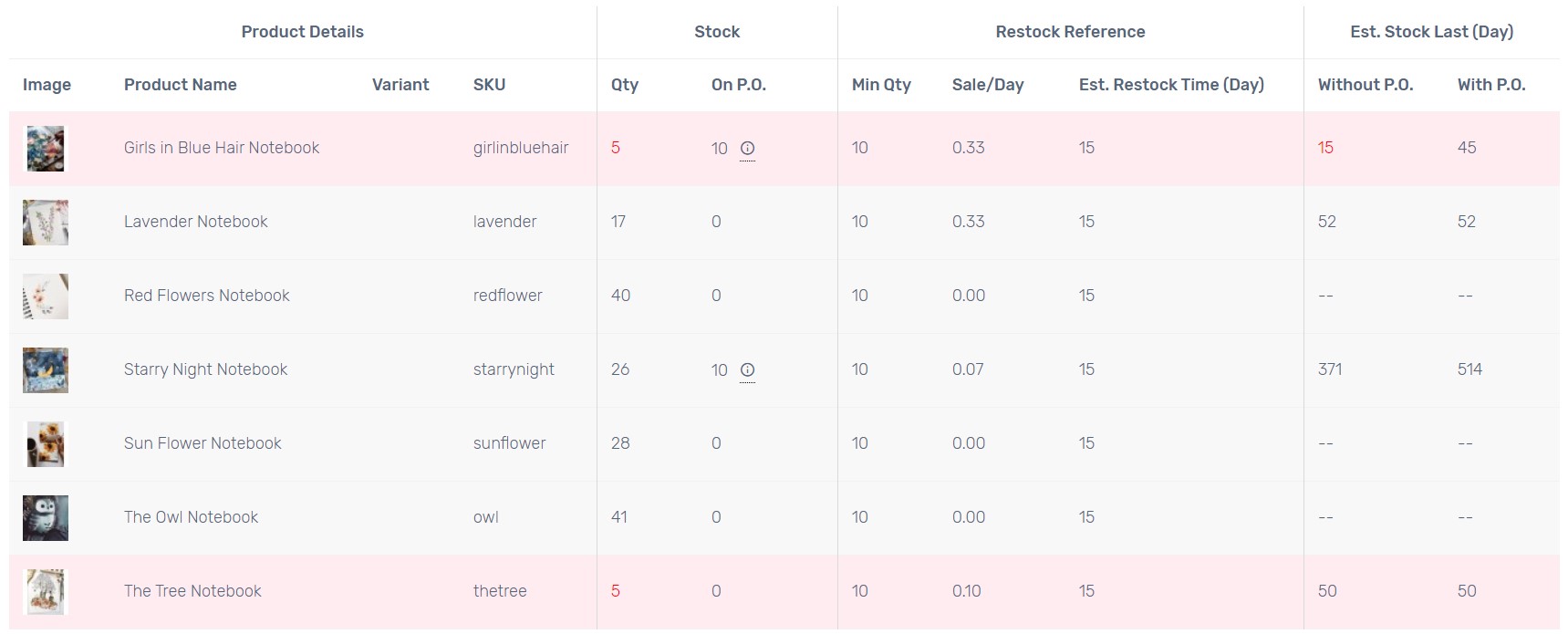

Step 2: View the Report Result

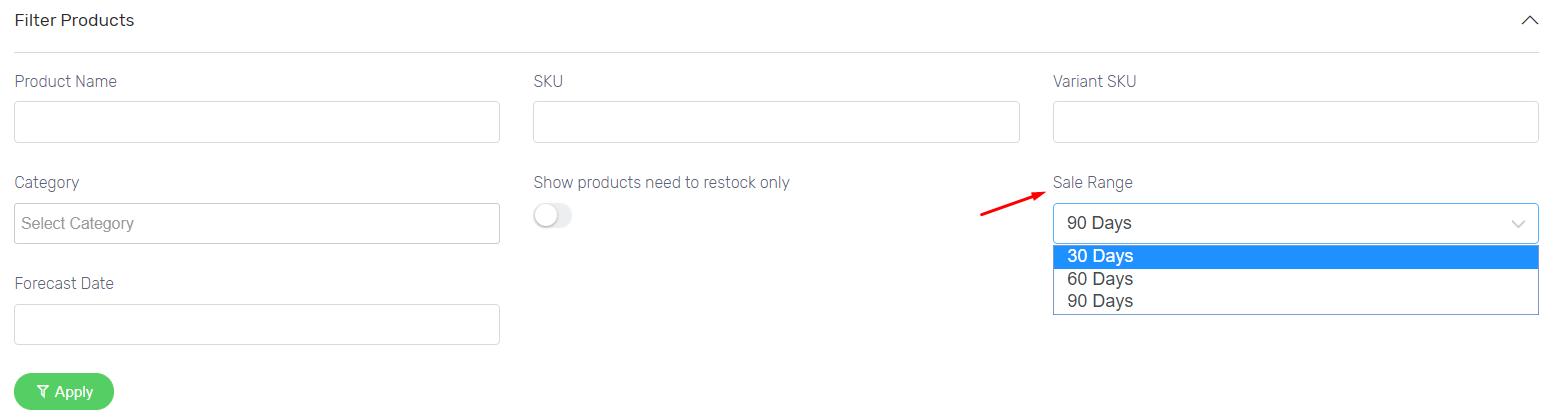

1. Filter the report based on the Sale Range: 30 days / 60 days / 90 days. Then, click on the Apply button.

2. The result after the filter will then be shown.

The column where it shown in Red Highlight will be the product that needed to be restock.

Kindly refer to the detailed explanation below.

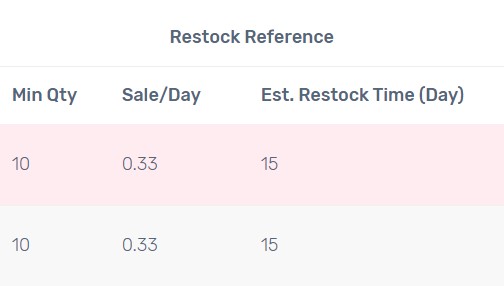

Restock References

Min Qty and Est. Restock Time (Day) are the information which updated earlier.

Sale/Day = Quantity Purchased ÷ Sale Range

For example, there are 10 quantity purchased in between the time of last 30 days (Sale Range), hence each day there are 0.33 sales.

Est. Stock Last (Day)

Without P.O. = Current Quantity ÷ Sale/Day

For example, the current in stock quantity is 5 and the sale per day will be 0.33. Hence, this stock is estimated that it can last for 15 days more.

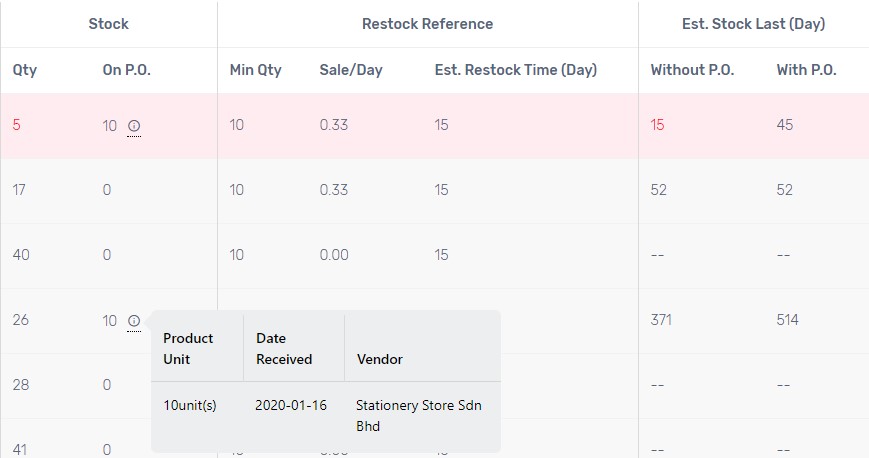

With P.O. = [Current Quantity + Quantity on P.O] ÷ Sale/Day

For example, the current in stock quantity is 5 and the sale per day will be 0.33. However, there is a Purchase Order made with the quantity of 10. Hence, this stock is estimated to be last for 45 days more.

Note: Click on the information icon ⓘ to view the Purchase Order (P.O.) details.

Additional Information

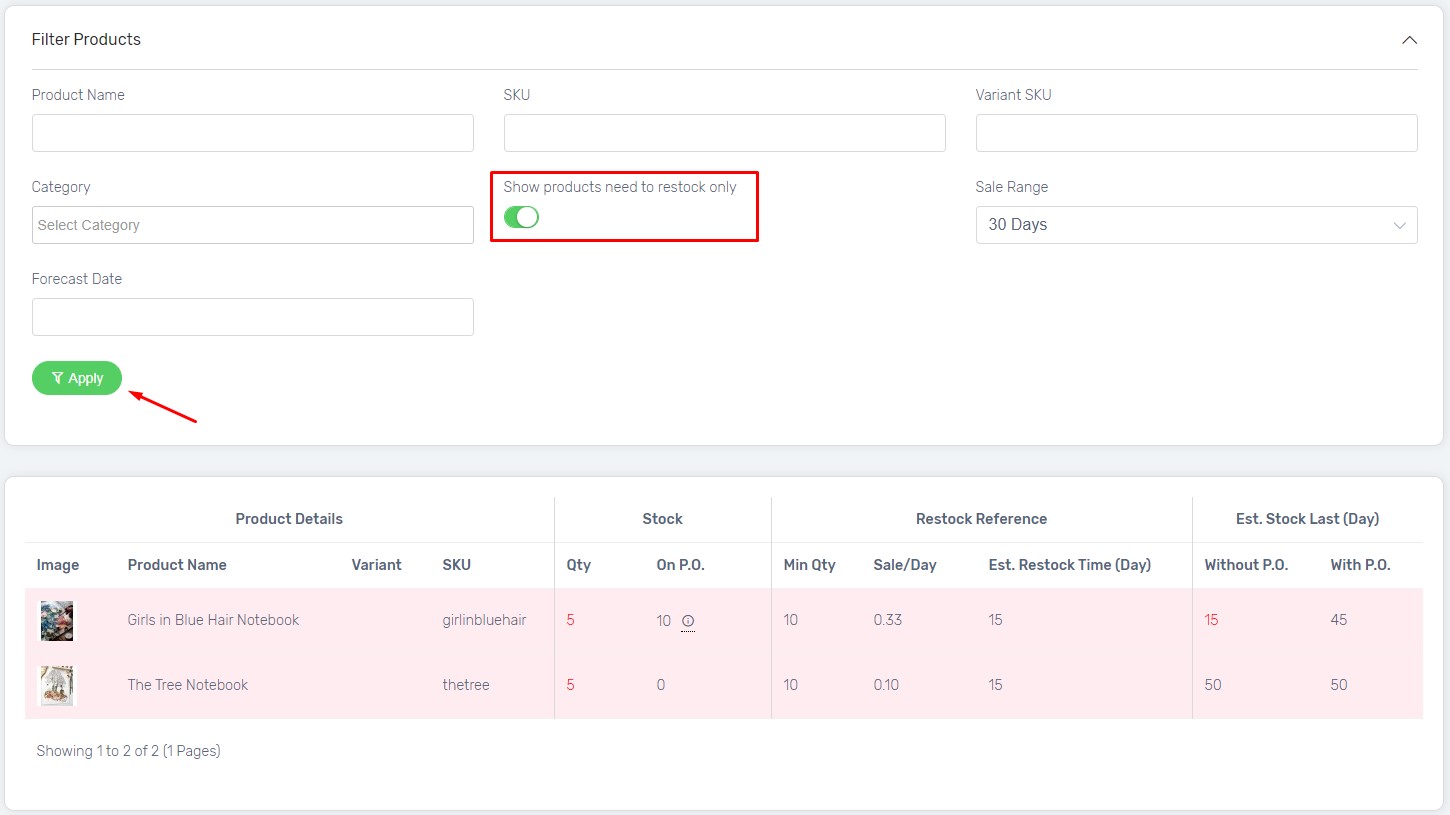

1. Display Products Need to Restock Only

Filter with option “Show products need to restock only” status enabled. Hence, it will only show the product list where it required to be restock.

2. Export Products Need to Restock into CSV

Click on the More at the top right, hence choose Export Reporting Product need to restock. The product where required to be restock will be exported out as in CSV file for better management.

3. Forecast Date

Filter a Forecast Date to check whether the stock will still able to last if the forecast date is reached. The column where it shown in Red Highlight will be the product that needed to be restock before the Forecast Date.